- Community Home

- >

- Services

- >

- The Cloud Experience Everywhere

- >

- Are you ready for Industry 4.0? HPE edge technolog...

Categories

Company

Local Language

Forums

Discussions

Forums

- Data Protection and Retention

- Entry Storage Systems

- Legacy

- Midrange and Enterprise Storage

- Storage Networking

- HPE Nimble Storage

Discussions

Discussions

Discussions

Forums

Discussions

Discussion Boards

Discussion Boards

Discussion Boards

Discussion Boards

- BladeSystem Infrastructure and Application Solutions

- Appliance Servers

- Alpha Servers

- BackOffice Products

- Internet Products

- HPE 9000 and HPE e3000 Servers

- Networking

- Netservers

- Secure OS Software for Linux

- Server Management (Insight Manager 7)

- Windows Server 2003

- Operating System - Tru64 Unix

- ProLiant Deployment and Provisioning

- Linux-Based Community / Regional

- Microsoft System Center Integration

Discussion Boards

Discussion Boards

Discussion Boards

Discussion Boards

Discussion Boards

Discussion Boards

Discussion Boards

Discussion Boards

Discussion Boards

Discussion Boards

Discussion Boards

Discussion Boards

Discussion Boards

Discussion Boards

Discussion Boards

Discussion Boards

Discussion Boards

Discussion Boards

Discussion Boards

Community

Resources

Forums

Blogs

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Receive email notifications

- Printer Friendly Page

- Report Inappropriate Content

Are you ready for Industry 4.0? HPE edge technologies and services can get you there

The fourth industrial revolution is upon us. Here are the key technologies that will shape your journey.

By Dimitris Koukas, Solutions Architect, HPE Networking, Workplace & Intelligent Edge practice

In 2016, the theme for the World Economic Forum Annual Meeting in Davos-Klosters, Switzerland, was “Mastering the Fourth Industrial Revolution.” It was a major milestone, marking the fact that today’s industries produce goods by adopting advanced technologies such as artificial intelligence (AI), machine learning (ML) and the Internet of Things (IoT).

Historically, each industrial revolution was characterized by a specific technology that would massively evolve the way industries worked:

The first industrial revolution changed the way people worked by utilizing steam and water power.

The second industrial revolution, or technological revolution, brought into the production environment a variety of new technologies such as electricity, railroads and telegraph networks, improving the mass production and transportation of goods.

Industry 3.0 – the digital revolution – leveraged computerization and improved workers’ experience by removing manual workflows and bringing automation to the table. Because more machines were deployed, mass production was improved in quality and quantity.

The latest industrial trend, Industry 4.0, continues what Industry 3.0 started by extending computerization and automation even further and by deploying AI, ML, and IoT. In transportation, autonomous vehicles can operate with little human input, and we’re moving closer to fully self-driving cars. AI and IoT systems have reduced the need for maintenance teams to run routine health checks on production machinery to assess its condition. In addition, there are now production lines that never stop because the machinery is autonomous with self-healing capabilities.

The Elements of Industry 4.0

We are already in the midst of Industry 4.0. Companies are enabling supercomputing, ML, IoT, mobility, cloud, autonomous machinery, autonomous vehicles, and robotics, and integrating them across supply chain and production environments. Let’s look at some of the key technologies:

Robotics and autonomous systems can be deployed on industrial assets for condition monitoring and predictive maintenance. Autonomous systems, with the aid of AI, include self-healing capabilities that can ensure maximum production uptime, lower maintenance costs, and extended equipment life.

Digital Twin technologies replicate the production environment, enabling workers to receive best-in-class training. In this way employees can experience a test environment simulating a real production line, where they can experiment and play around with the virtual machinery.

Augmented Reality (AR). Field engineers working in remote areas where the technical experts cannot be next to them can greatly benefit from AR. They can have full access to full-fledged AR capabilities on their phones and laptops, simplifying their daily work.

Mobility and cloud are here to stay, and will continue to propel Industry 4.0. Services that used to run only in traditional data centers can now be provided securely through public or private clouds.

Companies are increasingly taking advantage of the mobility capabilities provided by public cloud. However, not all services can be migrated to the public cloud, because of security, cost or architecture considerations. But there is always the safe option of replicating the cloud environment on-premises with a pay-as-you-go model such as HPE GreenLake. With this as-a-service model, users benefit from the ease and simplicity of the cloud experience in their own data center, edge location or co-location facility, while ensuring a secured and fully controlled environment.

One of the most attractive aspects of this cloud services approach is its financial flexibility. In particular, C-suite members don’t need to take the hard decision to make a heavy upfront investment, as would be required in a traditional procurement model. Instead, they can take advantage of monthly billing similar to the metering experience they know from the public cloud – but for infrastructure in their own data center.

The Intelligent Edge is another key technology in Industry 4.0. This is any area outside of the data center where things are happening, where large amounts of data are produced, often requiring immediate processing – for example, remote offices, factories, and oil rigs. In these locations we can enhance the data analytics by adding powerful compute such as HPE Edgeline.

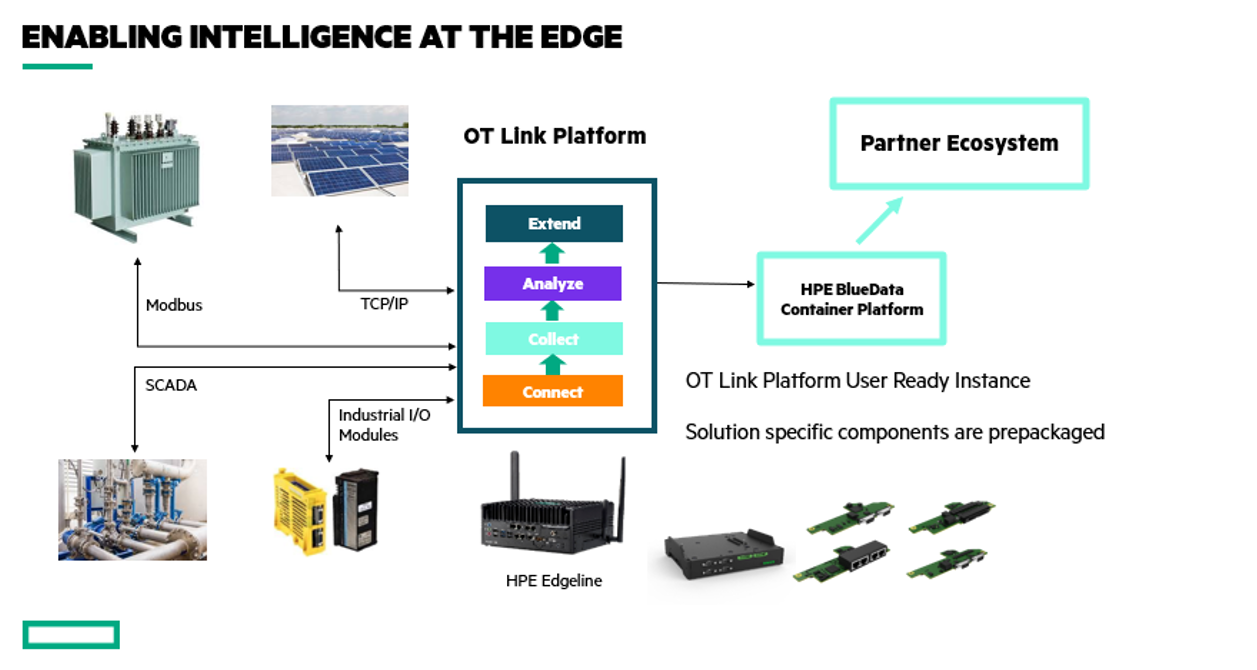

HPE Edgeline servers are capable of understanding protocols such as SCADA, Modbus, TCPIP or even legacy protocols such as Backnet and Serial, translating their data into meaningful insights. Of course, if a company has adopted a cloud strategy, data can be sent from the Edgeline server to the cloud; this will be the case when more resources are required for running the analytics. And if we need to engage data scientists to process the data, then HPE BlueData Container Platform would be the ideal solution, as seen in the figure below:

The Internet of Things, closely related to the Edge, is the most important element of the Fourth Industrial Revolution. Industries have huge numbers of sensors producing massive amounts of data. This data should be interconnected, collected and analyzed properly to provide useful insights. Data can also be processed, with the aid of AI and ML, for taking decisions on the spot, whether we’re talking about the self-healing of a piece of machinery or optimization decisions in a production line.

Again, the figure above describes these workflows. In this diagram we see that all data is connected with an Edgeline server (the OT Link Platform). This compact and robust compute is collecting all of the data and analyzing it on the spot, avoiding transmission delays which might delay an important decision.

Challenges in the journey to Industry 4.0

We see many areas that need to be considered for a successful journey into the latest Industrial Revolution. Let’s take a look at some important questions to ask as you embark on the journey:

- Can you find the right support? Few vendors can provide support in all of the areas I’ve described.

- Does your organization have the number of qualified resources that are needed to manage complex solutions?

- Where do you start such a transformation?

- Do you have the capital to invest in this journey?

- Is the networking infrastructure robust and agile enough to support autonomous decision-making?

For many businesses, the answers to these questions will be found by choosing the right technology partner.

HPE – the right partner for your journey

Why HPE? I will start answering this question by pointing to the strong capabilities of HPE Pointnext Services. This is a global services organization with a very large portfolio of capabilities, operating in multiple domains. To deliver many of our comprehensive Industry 4.0 solutions we work with our partner ecosystem, assuring an end-to-end successful solution in a turn-key manner, and often acting as a system integrator.

With more than 15,000 IT experts globally and a presence in more than 200 countries, our goal is to help you align business objectives and technology. A major differentiation from the competition is the expertise that we’ve acquired from delivering more than 11,000 IT projects per year, ensuring faster time to value and successful results for our customers.

HPE Pointnext Services can guide you through every step of your transformation journey. We’re with you for the entire project lifecycle, with our:

Advisory services. In the initial phase, HPE Pointnext Services experts run workshops with customers in order to understand their current state and the desired outcomes for the business. After completion of the workshops, the next step is to architect a transformational blueprint. Validation of the blueprint is done via proof of concept or a pilot to ensure that the proposed solution will generate the required customer outcomes.

Professional services. After ensuring a successful pilot or PoC, the next step is to design and configure the IT solution at scale in order to replicate the outcomes in the entire production environment. This will help to deploy and implement the solution rapidly. In the case of a brownfield environment, this is the stage for integrating the new solution into current production.

Operational services. If a company lacks the resources to run the new environment – either because of a lack of specialized expertise or a decision to invest people into developing the business rather than operations – then HPE Pointnext Services can operate and support the solution end-to-end.

Most importantly, we are right there with you, helping you to optimize with flexible delivery and consumption models and assuring a successful journey into Industry 4.0.

Learn more about HPE edge technologies.

Services Experts

Hewlett Packard Enterprise

twitter.com/HPE_Pointnext

linkedin.com/showcase/hpe-pointnext-services/

hpe.com/pointnext

- Back to Blog

- Newer Article

- Older Article

- Deeko on: The right framework means less guesswork: Why the ...

- MelissaEstesEDU on: Propel your organization into the future with all ...

- Samanath North on: How does Extended Reality (XR) outperform traditio...

- Sarah_Lennox on: Streamline cybersecurity with a best practices fra...

- Jams_C_Servers on: Unlocking the power of edge computing with HPE Gre...

- Sarah_Lennox on: Don’t know how to tackle sustainable IT? Start wit...

- VishBizOps on: Transform your business with cloud migration made ...

- Secure Access IT on: Protect your workloads with a platform agnostic wo...

- LoraAladjem on: A force for good: generative AI is creating new op...

- DrewWestra on: Achieve your digital ambitions with HPE Services: ...