- Community Home

- >

- Storage

- >

- Around the Storage Block

- >

- How LTO tape can safeguard 3D printing intellectua...

Categories

Company

Local Language

Forums

Discussions

Forums

- Data Protection and Retention

- Entry Storage Systems

- Legacy

- Midrange and Enterprise Storage

- Storage Networking

- HPE Nimble Storage

Discussions

Discussions

Discussions

Forums

Discussions

Discussion Boards

Discussion Boards

Discussion Boards

Discussion Boards

- BladeSystem Infrastructure and Application Solutions

- Appliance Servers

- Alpha Servers

- BackOffice Products

- Internet Products

- HPE 9000 and HPE e3000 Servers

- Networking

- Netservers

- Secure OS Software for Linux

- Server Management (Insight Manager 7)

- Windows Server 2003

- Operating System - Tru64 Unix

- ProLiant Deployment and Provisioning

- Linux-Based Community / Regional

- Microsoft System Center Integration

Discussion Boards

Discussion Boards

Discussion Boards

Discussion Boards

Discussion Boards

Discussion Boards

Discussion Boards

Discussion Boards

Discussion Boards

Discussion Boards

Discussion Boards

Discussion Boards

Discussion Boards

Discussion Boards

Discussion Boards

Discussion Boards

Discussion Boards

Discussion Boards

Discussion Boards

Community

Resources

Forums

Blogs

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Receive email notifications

- Printer Friendly Page

- Report Inappropriate Content

How LTO tape can safeguard 3D printing intellectual property and help forge new revenue streams

With the 3D printing industry projected to be $40-50 billion by 2025, find out why LTO Ultrium tape is the perfect solution for protecting 3D IP and helping forge new revenue streams.

Or started using a new product that didn’t work correctly because one piece of the assembly was badly manufactured or defective?

Such occurrences might become a thing of the past in the near future. Like mobile technology and the Internet of Things, 3D printing is going to transform society and business. 3D printing will permit more people to manufacture objects than ever before, leading some experts to refer to its potential as the Second Industrial Revolution. The value of the 3D printing, or additive manufacturing (AM), market could be worth somewhere between $40-50 billion by 2025.

Why is Additive Manufacturing witnessing explosive growth?

Significant benefits come from using 3D printing in R&D and manufacturing, including flexibility, cost reduction, supply chain optimisation and the ability to create less dense, lighter and stronger. An Airbus 350 aircraft, for example, contains over one thousand 3D-printed parts. With the backlog of orders for Airbus and Boeing standing at more than 13,000 aircraft, there is enormous commercial pressure—and reward—in finding ways to make aircraft production faster and less complex.

But markets that grow fast often generate unforeseen challenges as users adapt and invent workflows. And a recent report, Aviation Cybersecurity highlights how 3D printing will create new cyberrisks that will almost certainly need strategic focus.

The author of the report, Pete Cooper, summarises the threat:

“There have been several research projects covering cybersecurity vulnerabilities in AM. In one project, researchers found that it was possible to compromise either the printer or the design in such a way that the product was weakened in a manner undetectable with standard quality control methodologies. A different set of researchers demonstrated the ability to weaken a design by accelerating the fatigue life of a propeller so that it failed catastrophically after two minutes of use.”

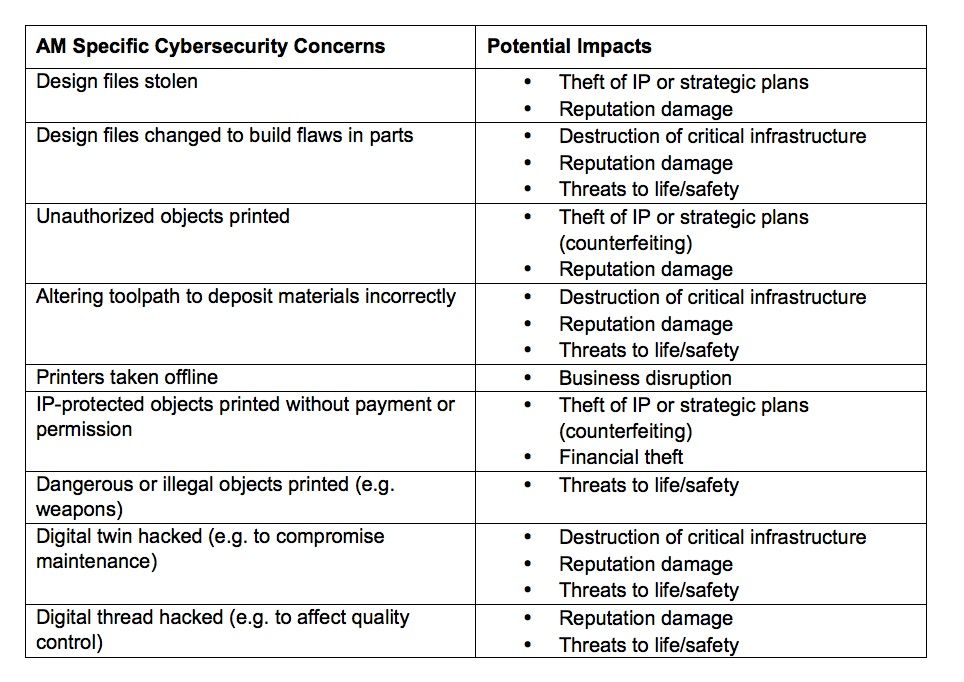

If left unguarded, AM workflows are vulnerable to compromise through multiple means. These include—but are certainly not limited to—disruption or deletion of firmware or product design, the compromise of intellectual property or sabotage of the printing process with the intention to weaken the products.

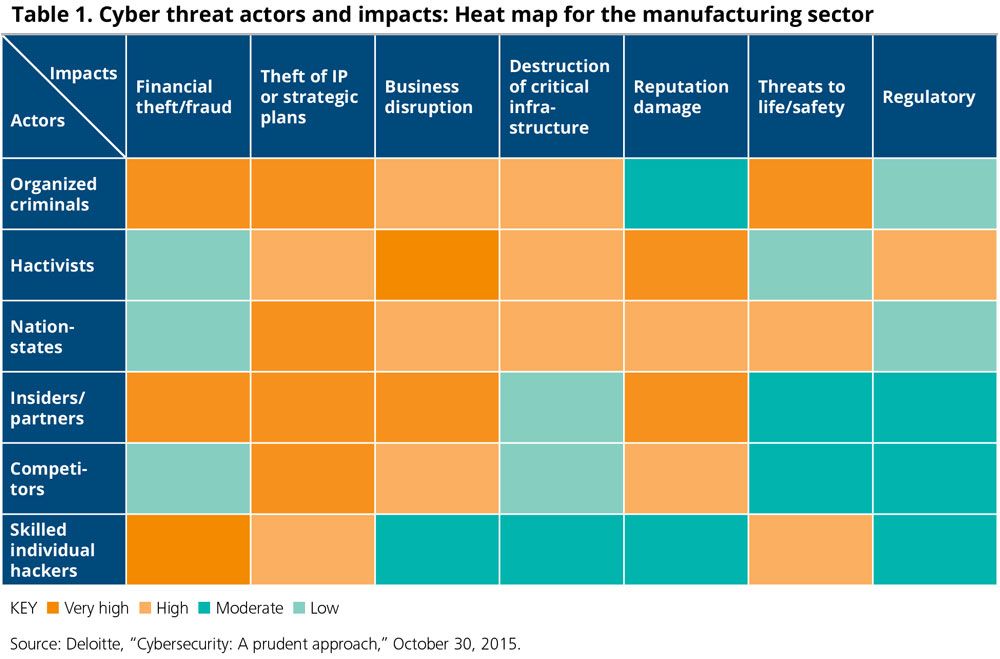

Examples of AM-specific cybersecurity concerns (source: Deloitte Insights, 2016)

While attempts to subvert 3D printing processes to endanger life and limb might be seen as an extreme, sabotaging a company’s product designs to slow down R&D, hinder manufacturing and damage customer perception, will probably be commonplace. As will stealing and reproducing copyright information to create low quality, inferior goods that can be sold and distributed online, making it hard for legitimate firms to address the damage to their brand. Such criminal activity could cost IP owners hundreds of millions, if not billions, of dollars.

AM opportunities: Mitigate risk and create new value using LTO Ultrium Tape

And yet, one of the most incredible opportunities afforded by AM is allowing companies to mine their legacy R&D investments through the sale and supply of a much broader range of parts for products that otherwise would become obsolete. Being able to make and sell spare parts, or their designs "on demand" would revolutionise the cost of storing and shipping components for items that are no longer being manufactured in volume. It could potentially create a new, hitherto untapped revenue stream from being able to make those parts available forever, without the need to consider production or materials sub-chains.

So how to balance the risk and reward by protecting these new AM workflows and outputs?

The answer is simple. HPE StoreEver LTO Ultrium tape. The marriage of this proven, reliable storage solution with cutting-edge additive manufacturing methods is compelling for addressing AM cybersecurity issues. Tape can guard against both the theft of 3D printing intellectual property as well as deliberate attempts to tamper with designs in such a way as to weaken or damage the finished output.

Whilst tape cannot address malicious interference with the actual printing process itself—e.g. if a hacker was able to intercept data being sent between host and printer, tape is a very effective means of protecting 3D intellectual property at rest. With built-in AES-256 LTO hardware encryption, data can be secured while writing to backup or archive, and once offline, it’s all but immune to digital tampering unless one was able to steal the physical cartridge itself. And even that would be pointless without the requisite encryption keys.

Keeping the CAD file offline and encrypted guards against hackers building in failure points in critical areas without the designers’ knowledge, which would then be included in any object printed from that file. For example, the ACAD/Medre.A worm steals CAD files; another example, CryptoLocker Malware, infects a file and locks it, rendering it inaccessible to the user unless a ransom is paid. Storing CAD designs on LTO tape would neutralise those threats completely.

Tape’s core strengths align with AM cybersecurity requirements

- The most cost-effective and scalable storage. It seems to me that LTO tape is a perfect fit for the ‘spare parts forever’ scenario that I described above. It would not make any sense to keep component levels for a for a long obsolete product on an expensive piece of storage like a flash array. Such a request might only be received a handful of times per year and the timing of those requests would typically be entirely non-linear. But information stored on LTO tape can be retained for up to 30 years - and to all intents and purposes indefinitely if the data is migrated to newer formats. Whilst the cost of storing that file is only a fraction of a cent, the value to the customer will be far greater.

- Simple and appropriate access. Nor is fast access to that design likely to be a paramount requirement for a customer who could have a 3D print task lasting several hours or even days awaiting them once they have downloaded the AM instructions. Linear Tape File System (LTFS) makes viewing the contents of a tape as easy as navigating a Windows, Linux or Mac desktop environment. A retrieval time of several minutes from archive tape is a perfectly acceptable trade off for being able to download the design for a component that otherwise would have been consigned to history. And of course, the supplier could always keep recently downloaded files on a disk cache in an "active archive" solution should some event happen to trigger a higher volume of requests—for example, the re-appearance of a classic toy in a movie or hit TV show.

- Keep and make availability legacy IP for profit. A number of solutions are being investigated to find ways of ensuring that customers who download a 3D printing CAD file cannot then simply copy or modify that information in an unauthorised manner—much like a streaming music service such as Spotify allow customers to fully access and listen to songs but not to duplicate or modify the source file itself. Tape could be the backbone of this innovation.

- Tape is faster than disk for streaming. This kind of workflow will be increasingly valid in the future for products and parts that may only ever have existed as CD or 3D printed designs. Some of these CAD design files can be very large—not large as in HD video but easily in excess of a few hundred megabytes. And the flexibility of CAD design and 3D prototyping makes it easy to generate lots of them. Again, tape is the ideal format for the fast streaming and efficient storage of these large individual files—more so than disk—and even the most prolific AM design process can be accommodated by a HPE StoreEver MSL3040 or MSL6480 tape library with their multi-petabyte capabilities.

I could envision R&D and design departments having dedicated tape libraries or active archive solutions for backing up and archiving their proprietary CAD information, using LTO encryption and even WORM (write once) tape in some instances to ensure that the AM designs are protected and incapable of modification by anyone except authorised users. Meanwhile, some other product marketing group would own converting that information at rest into a profit centre whilst still being able to satisfy the legal department’s desire for compliance and intellectual property protection.

How General Electric is revolutionising manufacturing with AM

GE is a good case study of just how phenomenally valuable 3D printing can be for enterprises. On one project for a new aero engine design, its R&D engineers were able to print half of the machine, reducing 900 separate components to just 16. The printed parts were 40 percent lighter and 60 percent cheaper (which has obvious environmental benefits too). To date, GE has received orders for over 12,000 over the new engines with a combined list price value of $170 billion.

One area that I haven’t space to get into in this blog post is the potential for securely storing 3D printing information in the field of medicine. Using AM methods to create organic material such as skin tissue and organs is a very real prospect for clinicians and researchers in treating disease and age-related illnesses in the future. Imagine being able to print a new kidney for a patient using their own genetic information? There would be no complications arising from the body rejecting the organ, as with conventional transplant surgery. In this field, the need for privacy, security and ensuring the integrity of the AM information would be paramount. Encrypted WORM tape might be a very viable, secure long term storage solution for this kind of patient data.

In conclusion, therefore, such is the volume of growth anticipated in Additive Manufacturing across just about every industry I can think of, it seems feasible that AM/3D Printing could be a significant opportunity for LTO Ultrium tape and LTFS in the future. Encrypted, offline tape storage can help this transformative industry achieve the full potential promised by the Second Industrial Revolution!

Who knows, we might even print LTO Ultrium cartridges using 3D technology one day. Watch this space!

- Back to Blog

- Newer Article

- Older Article

- haniff on: High-performance, low-latency networks for edge an...

- StorageExperts on: Configure vSphere Metro Storage Cluster with HPE N...

- haniff on: Need for speed and efficiency from high performanc...

- haniff on: Efficient networking for HPE’s Alletra cloud-nativ...

- CalvinZito on: What’s new in HPE SimpliVity 4.1.0

- MichaelMattsson on: HPE CSI Driver for Kubernetes v1.4.0 with expanded...

- StorageExperts on: HPE Nimble Storage dHCI Intelligent 1-Click Update...

- ORielly on: Power Loss at the Edge? Protect Your Data with New...

- viraj h on: HPE Primera Storage celebrates one year!

- Ron Dharma on: Introducing Language Bindings for HPE SimpliVity R...